Fence It Up: Your Guide to Installing a Sturdy Metal Fence

- Pro Fence Wilmington

- Aug 18, 2025

- 11 min read

Why a Professionally Installed Metal Fence is the Smart Choice

Understanding how to install a metal fence properly is key to a project that transforms your property’s security, privacy, and curb appeal. Whether you’re considering aluminum, steel, or wrought iron, metal fencing offers superior durability and weather resistance compared to wood alternatives, providing decades of reliable service when installed correctly.

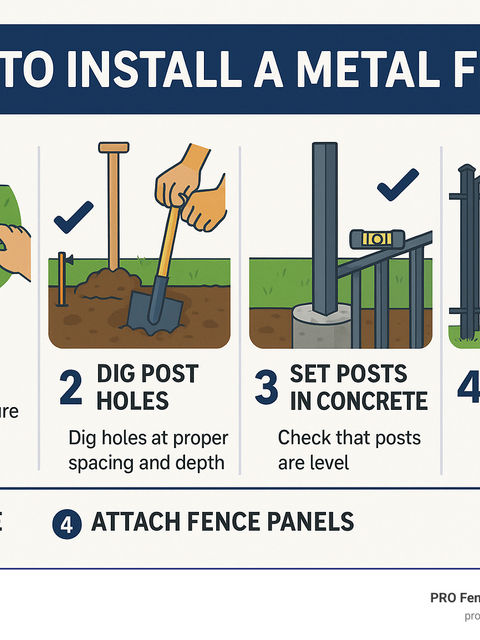

A Look at the Professional Process:

Plan and measure the fence line and verify local regulations.

Dig post holes at precise intervals, typically 6-8 feet apart, to a depth below the frost line.

Set metal posts in concrete, ensuring they are perfectly plumb and level.

Attach fence panels with manufacturer-specified brackets after the concrete cures.

Install gates and add finishing touches like post caps.

Metal fencing is a popular choice for Massachusetts homeowners. Industry data shows that metal fence posts have a longer life expectancy than wooden fence posts and require minimal maintenance. Unlike wood that can rot, warp, or attract pests, metal maintains its structural integrity through harsh New England winters and humid summers.

The benefits extend beyond durability:

Improved security with strong, tamper-resistant construction

Low maintenance requiring only occasional cleaning

Weather resistance that withstands extreme conditions

Increased property value through improved curb appeal

Versatile design options from decorative aluminum to utilitarian chain link

While some homeowners consider a DIY approach, professional installation ensures the job is done right. The process is complex, requiring specialized tools and knowledge to ensure the fence stands strong for decades. Professional installers may charge anywhere from $30 to over $100 per linear foot, a cost that reflects the expertise needed for a lasting, high-quality result.

Easy how to install a metal fence glossary:

Before You Begin: Planning Your Metal Fence Project

Understanding the process of how to install a metal fence helps you make informed decisions for your property. The most successful fence projects begin with careful planning, long before the first post hole is dug. This phase is the foundation for success, preventing issues with city codes, neighbors, or the fence itself.

Good planning saves time and money, ensuring the right materials are chosen for your needs and that all local rules are followed. It also helps establish a realistic budget.

Choosing the Right Metal Fence for Your Needs

Metal fencing offers great variety, and the right choice depends on your goals. Are you looking for maximum security, neat curb appeal, or budget-friendly functionality?

Aluminum fencing is a homeowner favorite. It’s lightweight, rust-resistant, and available in ornamental designs that mimic wrought iron. It’s an excellent choice for pool areas or adding elegance, and its panels can often be “raked” to follow sloped ground. Our Aluminum Fencing options showcase its versatility.

Steel fencing is the heavyweight champion for durability. When galvanized, it offers incredible strength and rust resistance. Corrugated steel panels provide a modern look with excellent privacy, while steel palisade fencing is a top choice for security.

Wrought iron fencing offers timeless elegance. Modern versions are typically made from steel or aluminum, making them lighter and easier to maintain. It is highly customizable and can significantly boost property value.

For functionality and budget, Chain Link Fencing is a reliable choice. It’s secure, durable, and requires minimal maintenance. Privacy slats can be added if needed.

Fence Type | Cost (Material Only) | Durability | Maintenance | Best Use |

|---|---|---|---|---|

Aluminum | Moderate | High | Low | Decorative, Pool, Boundary, Curb Appeal |

Steel | Moderate to High | Very High | Moderate | Security, Privacy (corrugated), Industrial |

Wrought Iron | High | Very High | Moderate | Decorative, High Security, Classic Aesthetic |

Chain Link | Low | High | Very Low | Utility, Pet Enclosures, Security, Affordability |

Understanding Costs and Materials

Professional metal fence installation typically runs $20 to $100 per linear foot, based on national internet data (these are average costs, not actual quotes for PRO Fence Co. Wilmington). This wide range reflects the variety in materials, project complexity, and regional labor rates.

Material costs alone vary significantly. Chain link might cost $8 to $30 per linear foot, while premium wrought iron can reach $30 to $100 per linear foot. Aluminum typically falls in the $25 to $80 range, and corrugated steel runs $20 to $65 per linear foot.

Your project’s final cost is most affected by fence height and length. Site conditions also play a role; rocky soil, steep slopes, or removing an old fence can add $10 to $35 per linear foot.

Don’t forget extras like gates, which can range from $200 to $1,000 for basic models or $2,000 to $7,000 for automatic systems. Permits, usually required for fences over a certain height, typically cost $50 to $200.

Essential Tools and Preparation for Metal Fence Installation

Proper preparation is what separates a successful project from a costly one. A professional installer handles all these critical steps.

Site preparation begins with clearing the fence line of any brush or debris. The next, most critical step is to Call 811 Before You Dig. This free service marks underground utility lines, preventing dangerous and expensive accidents. This call must be made a few business days before work begins.

Simultaneously, an installer will check local building codes and HOA requirements. Regulations on height, setbacks, and materials vary widely. They will also confirm property lines using a deed or plat map to prevent any disputes with neighbors, typically installing the fence a few inches inside the boundary.

Professionals arrive with all the necessary tools for a safe and efficient installation, including a post hole digger or auger, level, string line, concrete mixer, drill, and essential safety gear.

A Look at the Professional Installation Process

With planning complete, the physical installation begins. This is where expertise in how to install a metal fence turns materials into a sturdy, beautiful structure. A professional approach ensures every step is handled methodically, resulting in a fence that will stand strong for decades.

Rushing the installation process leads to crooked posts, sagging panels, or worse. A professional team takes the time to get each stage right.

Step 1: Layout and Digging Post Holes

Proper layout is crucial. Professionals start by creating a perfectly straight fence line using stakes and a taut string line. This guide ensures precise post placement for a clean, professional look. They use proven methods, like the 3-4-5 rule, to ensure corners are perfectly square.

Post locations are marked along the string line, with standard spacing of 6 to 8 feet apart (center to center), though this is always confirmed with the fence manufacturer’s specifications. This spacing provides optimal support without wasting materials.

Next, the digging begins. Each post hole is dug to one-third the post’s height plus an extra 6 inches for gravel. In Massachusetts, it’s critical to dig below the frost line to prevent frost heave from pushing posts out of alignment over winter. Holes are typically 8 inches in diameter to allow for concrete. A 6-inch layer of gravel is added to the bottom of each hole for drainage and a stable foundation.

Step 2: Setting the Metal Fence Posts

This step gives the fence its backbone. Metal posts have a longer life expectancy than wooden fence posts because they don’t rot, warp, or attract pests. They are highly weather-resistant, a key benefit in New England’s varied climate.

Professionals always set posts in concrete for maximum stability. A quick-setting concrete is mixed and poured around each post, which rests on the gravel base. The most critical part is ensuring each post is perfectly plumb (vertical) and aligned with the string line. A post level is used to check this from all sides.

One team member typically holds the post steady while another pours the concrete, filling the hole to about 2-4 inches below ground level. The top of the concrete is sloped away from the post to shed water and prevent rust. Temporary braces are then used to hold each post in its exact position while the concrete hardens.

Patience is key during the curing process. Installers wait at least 24-48 hours before attaching panels, and often up to a week for heavy gates, to ensure the concrete reaches maximum strength.

Step 3: Attaching the Fence Panels and Rails

Once the posts are securely set, the fence takes shape as panels are attached. This is the most visually rewarding part of the installation.

Most metal fence systems use specific brackets and fasteners for attachment. An organized approach ensures all hardware is ready. Panels are lifted into place, and brackets are attached first to the posts, then to the panels. This allows for minor adjustments before everything is fully tightened.

Proper alignment and consistent height are hallmarks of a professional job. Installers ensure each panel is level and maintains a consistent clearance from the ground (typically 2 inches) to prevent debris buildup. They use all manufacturer-recommended fasteners to guarantee stability. For chain link, this includes tensioning the mesh correctly to prevent sagging. Finally, a thorough check ensures every fastener is tight, preventing rattles and loose panels for years to come.

How Professionals Tackle Slopes, Gates, and Common Issues

Even with careful planning, fence installations can present challenges. Experienced installers know how to handle sloped yards, tricky gate installations, and unexpected obstacles, ensuring a seamless result no matter what the property throws at them.

Key Considerations for Installing a Metal Fence on Uneven Terrain

Installing a fence on a slope is manageable with the right technique. The choice depends on the steepness of the grade and the desired look.

Racking: For gentle slopes, racking is the best method. It allows the fence panels to follow the ground’s natural contour, creating a smooth, flowing line. Many aluminum panels are designed to be “rackable,” pivoting at the posts to accommodate the angle.

Stepping: For steeper slopes, stepping is preferred. Each panel remains level, and the post heights are adjusted to create a stair-step effect. This provides maximum stability on challenging terrain and requires careful planning for a visually appealing result.

Professionals can assess a property and recommend the best approach. For more details on these techniques, see our resource on installing fences on slopes.

Installing a Metal Fence Gate

A gate is often the most complex part of an installation. A professionally installed gate swings smoothly and latches securely every time.

This requires precise measurement of the gate opening to account for the gate, hinges, and latch hardware. Gate posts bear more stress and must be set deeper in concrete and braced more securely than line posts. Installers always let the concrete cure for at least 24-48 hours, and often longer, before hanging the gate to ensure a strong foundation.

Hanging the gate and installing the latch are done with precision to ensure perfect alignment and prevent binding, ensuring the gate is easy to use for years to come.

Overcoming Common Installation Challenges

Professional installers have seen it all and know how to handle common issues:

Incorrect post spacing: Meticulous measurement prevents this, but if an adjustment is needed, pros have techniques to correct it without compromising the fence’s integrity.

Posts that aren’t plumb: Using a quality level and proper bracing during curing prevents this. A crooked fence is a sign of an amateur job.

Panel alignment issues: A string line and careful adjustments before final tightening ensure all panels are perfectly aligned and level.

Underground obstacles: This is why calling 811 is non-negotiable. If rocks or roots are encountered, installers have the tools and experience to work around them, sometimes by adjusting the fence line slightly.

Rushing the concrete curing time: Professionals know that patience is critical. They will never put stress on posts before the concrete is fully cured, guaranteeing the fence’s long-term stability.

When how to install a metal fence involves these complexities, professional help is the surest path to a successful outcome.

Finishing Touches: Maintenance and Professional Help

Congratulations! Your new metal fence is standing tall and looking fantastic. A key benefit of metal is that a little ongoing care is all that’s needed to keep it performing well for decades.

Metal Fence Maintenance Requirements

The best news about understanding how to install a metal fence is that the maintenance is refreshingly simple, especially compared to wood fences that need constant upkeep.

Regular Cleaning: A simple spray with a garden hose once or twice a year is usually enough to remove dust and debris. For stubborn spots, a soft sponge with mild, soapy water will do the trick.

Periodic Inspections: A quick walk along the fence line every few months to check for loose fasteners or any signs of wear is a good habit. Pay special attention to gate hinges and latches.

Rust Prevention: Quality aluminum is naturally rust-resistant, and galvanized steel has a protective coating. If a scratch or chip does occur, it can be easily addressed by cleaning the area, applying a rust-resistant primer, and touching it up with matching paint.

Hardware Maintenance: Check that screws and bolts are tight once a year. Temperature changes can cause minor loosening over time, and a quick tightening keeps everything secure.

For more detailed guidance, our Fence Repair & Maintenance page offers comprehensive tips.

The Value of a Professional Fence Installer

While it’s good to understand the installation process, the project itself is often best left to professionals. There are many situations where hiring an expert is the smartest choice.

Complex Projects: Properties with steep slopes, multiple elevation changes, or intricate layouts require the experience and specialized tools that professionals bring.

Time Constraints: A proper fence installation is time-intensive. A professional crew can complete a project in a fraction of the time it would take for a weekend DIY effort.

Tool and Material Expertise: Professionals have the right equipment and know the best materials for the local climate and soil conditions, ensuring a durable, long-lasting result.

Warranty Protection: Reputable fence companies provide warranties on both materials and workmanship. This protects your investment and provides invaluable peace of mind.

Based on national internet data, professional installation typically ranges from $20 to $100 per linear foot installed. This investment covers expert installation, proper permits, warranty coverage, and the assurance that the job is done right the first time.

For homeowners in Wilmington, MA, and the surrounding areas, our team understands the unique challenges of New England weather. Find qualified experts through our Fence Installers Near Me page.

Frequently Asked Questions about Metal Fence Installation

We enjoy helping homeowners understand the ins and outs of metal fence installation. Here are some of the most common questions that arise during the planning phase of a fence project.

How far apart should metal fence posts be?

This is a critical question, as proper post spacing is essential for a sturdy fence. The general rule is 6 to 8 feet apart, measured from the center of one post to the center of the next. This provides the necessary support for most fence panels.

However, a professional installer will always follow the manufacturer’s specifications first. Different fence systems have precise requirements. For example, some ornamental fences require exact spacing to the half-inch to fit correctly. Getting this right is a key part of a professional installation that ensures a perfect fit and long-term strength.

Do metal fence posts always need to be set in concrete?

For a permanent, high-quality fence, the answer is yes. We highly recommend setting metal posts in concrete for maximum stability and longevity. Concrete acts as an anchor, preventing posts from shifting due to wind, soil movement, or frost heave during New England winters.

This is especially critical for gate posts and corner posts, which are under significantly more tension than line posts. While some temporary or lightweight fences might use driven anchors, a professional, warrantied installation relies on concrete for a foundation that will last for decades.

Can you attach wood fence panels to metal posts?

Absolutely. This hybrid approach is quite popular because it combines the strength and longevity of metal posts with the classic, warm aesthetic of wood panels. It’s an excellent way to get the best of both worlds.

Professionals use special brackets designed to securely connect wood rails to metal posts. When installing these hybrid fences, it’s important to use galvanized fasteners to prevent rust and pressure-treated wood for the panels to prevent rot. This combination results in a beautiful fence that is built to last.

Secure Your Property with a Perfectly Installed Fence

There’s a deep satisfaction in admiring a perfectly installed metal fence—knowing your property is more secure, your curb appeal is improved, and you’ve made a lasting investment.

Throughout this guide, we’ve explored the details of how to install a metal fence, from planning and material selection to the final touches. The process highlights why metal fencing offers superior durability compared to other materials, standing strong through harsh New England winters and humid summers.

Whether you choose the clean look of aluminum, the strength of steel, or the classic beauty of wrought iron, proper installation is the key to longevity. A fence that is professionally planned, precisely measured, and securely anchored will protect and beautify your property for years to come.

For homeowners in Wilmington, MA, and surrounding areas in Middlesex and Essex Counties, the smartest investment is often trusting the experts. The team at PRO Fence Co. Wilmington brings years of local experience to every project, understanding the unique challenges of our climate and terrain. We provide personalized and professional fence services that remove the guesswork from your project.

Our family-owned approach means we treat every installation with the care it deserves. We know a fence is more than a boundary—it’s part of the space where your family will make memories.

Ready to transform your property with a professionally installed metal fence? Contact us for a free estimate and let us show you why quality craftsmanship and personalized service make all the difference.

Comments